In dense urban construction—where access roads are narrow, staging space is limited, and labor is constantly stretched—concrete supply becomes a scheduling bottleneck. The equipment decision is rarely about “bigger is better”; it is about continuous workflow, safe maneuvering, and stable mix quality with minimal onsite footprint.

City projects often fail to hit daily pour targets for reasons unrelated to design or crew capability. Most delays come from predictable site constraints:

Pump, rebar, formwork, pallets, excavator paths, and safety corridors all compete. A fixed mixing setup can occupy 50–150 m² including aggregate stock and loader movement.

When a workflow needs a loader operator + mixer operator + forklift/telehandler support, the “mixing system” becomes a staffing problem. One absence can cut output in half.

Urban pours often rely on short access windows, noise regulations, or traffic control permits. Every re-handling step (loading, transferring, waiting) adds compounding delay.

Traditional mobile batching solutions can work well on open sites. The challenge is that “mobile” does not always mean “tight-site friendly.” On constrained projects, the deciding factor is whether the mixing process can stay continuous without turning the site into a logistics puzzle.

| Selection Factor | Traditional Mobile Mixing Plant (Typical) | Self-Loading Mixer Truck (AS-5.5 Class) |

|---|---|---|

| Footprint & site layout | Needs setup area, aggregate storage, and loader travel lanes; often 50–150 m² total functional space. | Mixing + loading is integrated on one vehicle; staging can be simplified to smaller stock zones and safer traffic separation. |

| Material handling steps | Loader to hopper → batching → discharge to truck/pump; multiple handoffs and waiting points. | Onboard bucket loads aggregates directly—often removing one transfer step and reducing queue time. |

| Labor dependency | Commonly needs 2–4 operators depending on configuration and feeding method. | Often manageable with one trained operator plus standard site support for water/cement logistics. |

| Relocation within a project | Breakdown and re-setup can interrupt production, especially when permits restrict on-road movements. | Drive to the pour point or closer to it; reduces internal hauling and supports phased work zones. |

| Quality stability in stop-start conditions | Batch quality is good, but interruptions and multiple transfers can increase variability and contamination risk. | Continuous drum mixing during travel helps maintain workability; fewer transfers reduce segregation exposure. |

For many tight urban jobs, the most valuable gain is not just “mixing capacity”—it is the ability to keep concrete moving without needing an extra loader, an extra staging lane, or “one more person” to keep the sequence alive.

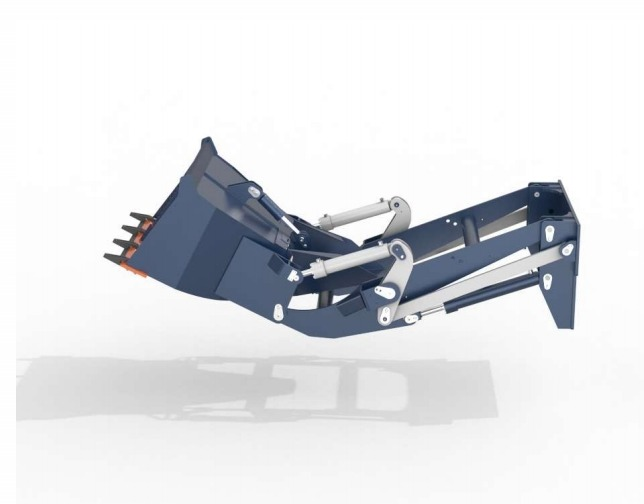

The AS-5.5 class self-loading concrete mixer truck is typically chosen when a project needs a compact footprint but cannot compromise on daily output. Two reference numbers define the operational range: 5.5 m³ drum capacity and a typical production rate around 22 m³/h (depending on material supply, operator skill, haul distance, and site traffic).

Tight sites punish “oversized” solutions in subtle ways. A high-capacity setup can still underperform if it increases internal traffic, creates new safety conflicts, or requires additional handling steps. In field terms, the win often sounds like: “We no longer need two vehicles shuttling wet concrete just to reach the pump.”

With a self-loading mixer truck, the core value is that loading, mixing, and moving are integrated. This tends to improve:

A practical selection method is to start with the pour schedule and work backward to equipment productivity—then pressure-test it against site layout and access constraints. The following table can be used as a planning reference (adjust based on travel distance, pump availability, and supply reliability).

| Urban Scenario | Typical Constraint | Planning Target | Why AS-5.5 Fits |

|---|---|---|---|

| Inner-city renovation / alley access | Narrow lanes, minimal staging, frequent stop-start | ~30–80 m³/day | Compact movement + integrated loading prevents repeated shuttling and reduces site congestion. |

| Basement / podium slab pours | Restricted access windows, queue control at pump | ~80–150 m³/day | ~22 m³/h planning rate supports steady pump feeding without building large buffer zones. |

| Municipal works (sidewalks, medians, drainage) | Moving workfront, segmented pours | ~40–120 m³/day | Drive-and-pour flexibility reduces downtime between segments and simplifies relocation. |

| Urban industrial infill / warehouse extension | Limited laydown due to active operations | ~100–200 m³/day | Large 5.5 m³ drum reduces cycles; fewer machines inside active plant improves safety. |

Information-graphic suggestion for your page: a “Footprint & Workflow Comparison” block showing (1) mixing plant + loader lanes vs (2) single self-loading unit + compact stock zones, with a simple top-down schematic and total area ranges.

For urban projects, equipment selection is increasingly audited—not only for productivity, but also for compliance and risk control. Buyers typically ask for documentation that reduces approval friction and supports tender requirements:

ISO 9001-style quality systems (inspection traceability, assembly checks, and test records) help reduce acceptance disputes and service uncertainty.

CE compliance is often requested in EU-oriented procurement or multinational contractor standards to simplify site approval and documentation review.

In practice, documentation does more than “tick a box.” It shortens the buyer’s internal review cycle—meaning equipment can reach the site earlier, when the schedule still has room to breathe.

Before committing to any solution for a narrow urban jobsite, experienced teams validate a few operational details that directly impact real output:

Get a practical planning pack built for narrow urban jobsites: output estimator (based on 5.5 m³ cycles), footprint comparison table, and a checklist for ISO/CE document requests—so your team can validate feasibility before mobilization.

Get the AS-5.5 self-loading concrete mixer truck selection toolkitRecommended for contractors managing tight access, phased pours, and labor-constrained schedules.