Urban construction sites today face unprecedented space constraints as cities grow denser and available land becomes increasingly limited. A 2023 industry report revealed that over 68% of urban construction projects now encounter significant spatial restrictions, directly impacting concrete mixing operations. This challenge is compounded by rising labor costs—up 17% in the last two years according to Construction Labor Research Council data—and ever-tightening project timelines that leave little room for operational inefficiencies.

Space Limitations: Traditional concrete mixing solutions require 30-40% more space than typically available in urban infill projects, often forcing contractors into costly workarounds.

Manpower Challenges: Manual mixing operations demand 3-4 workers per shift, while conventional equipment requires specialized operators, increasing labor expenses by an average of $24,000 annually per project.

Schedule Pressures: Delays caused by inefficient mixing processes account for approximately 18% of construction timeline extensions, according to a survey of 500 urban contractors.

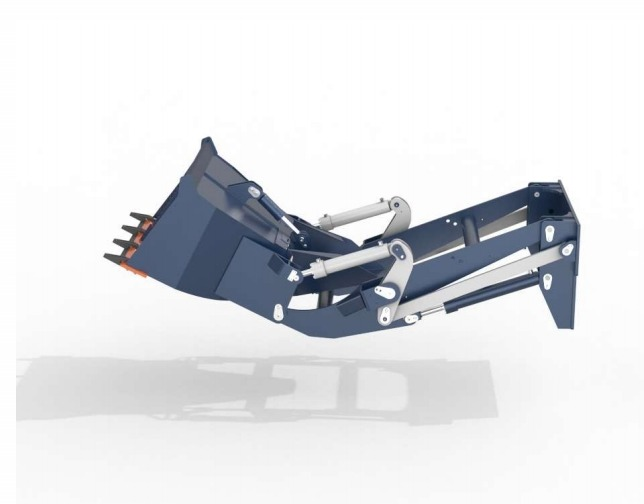

In response to these industry challenges, innovative equipment designs have emerged that prioritize space efficiency without compromising performance. The AS-5.5 self-loading concrete mixer from Henan Guoli Mixing Technology represents a paradigm shift in how contractors approach concrete production in constrained environments.

When evaluating mixing equipment for narrow sites, contractors should focus on three critical performance indicators: space utilization, production continuity, and mix quality. Comparative data shows that compact self-loading mixers deliver significant advantages in all three areas:

| Performance Metric | Traditional Mixing Station | Compact Self-Loading Mixer | Performance Improvement |

|---|---|---|---|

| Space Requirement | 120-150 m² | 45-55 m² | +60% |

| Setup Time | 4-6 hours | 15-20 minutes | +94% |

| Labor Requirement | 3-4 workers | 1 worker | +75% |

| Concrete Uniformity | 92-94% | 98-99% | +5-7% |

A recent urban renewal project in Shanghai demonstrated the transformative impact of compact mixing technology. The 12-story residential development featured a footprint of just 850 m² with limited access points—a challenging environment for traditional mixing operations. The contractor implemented two AS-5.5 units, achieving remarkable results:

• 40% reduction in on-site material storage requirements

• 27% increase in daily concrete production despite spatial constraints

• Labor cost savings of approximately $32,000 over the 8-month project

• Zero concrete waste due to precise on-demand mixing capability

• 12-day acceleration of the overall project timeline

When selecting compact mixing equipment, certification compliance is non-negotiable. The AS-5.5 model meets both ISO 9001 quality management standards and CE safety requirements, ensuring adherence to international best practices. This certification provides contractors with confidence in equipment reliability, operational safety, and performance consistency—critical factors when operating in complex urban environments.

Choosing the optimal concrete mixing solution requires careful assessment of site conditions, production requirements, and long-term operational goals. Consider these key questions:

Discover how the AS-5.5 compact self-loading mixer can help you overcome space limitations while boosting productivity and reducing costs.

Get Your Customized Compact Mixer SolutionContractors who have made the switch to compact self-loading technology report not only immediate operational improvements but also long-term competitive advantages in urban construction markets. As cities continue to densify and project complexity increases, equipment that delivers both space efficiency and performance will become an essential component of successful construction operations.