Key Insight: The dual helix mixing system integrated within the AIMIX AS-6.5 self-loading concrete mixer specializes in rapid, uniform mixing — pushing construction productivity beyond traditional benchmarks, crucial for large-scale projects demanding speed and consistency.

At the heart of the AIMIX AS-6.5 lies the innovative dual helix mixing mechanism, uniquely designed to optimize material blending in a way conventional single-screw mixers cannot. Featuring two counter-rotating helical blades, the system delivers simultaneous longitudinal and transverse shear forces. This action ensures an accelerated mixing cycle, drastically reducing the typical mixing time by up to 30% compared to traditional drum mixers. Operating at a capacity of approximately 6.5 cubic meters per batch, the system maintains consistent homogeneity with minimal segregation or dead zones.

The dual screw assembly rotates at variable speeds—optimally set between 20 and 35 RPM—allowing operators to adjust mixing intensity based on material type and project requirements. This flexibility delivers both versatility and precision, especially important in projects involving high-performance or specialty concretes.

| Parameter | Dual Helix System | Traditional Single-Screw Mixer |

|---|---|---|

| Mixing Time (per batch) | 6 minutes | 8.5 minutes |

| Mixing Uniformity (Coefficient of Variation) | 3.5% | 5.2% |

| Material Discharge Time | Under 3 minutes | 4+ minutes |

| Average Batch Output | 6.3 m³ | 5.8 m³ |

At the New Horizon Stadium project in Europe, deploying the AIMIX AS-6.5 self-loading mixer facilitated a remarkable construction speed-up. The project team reported a 25% reduction in concrete batch cycle time, directly linked to the dual helix mixing design. The uniformity of the mixed concrete translated into enhanced structural integrity and fewer post-pour corrections, cutting downtime and enhancing workforce productivity.

Additionally, onsite workers noted the mixer’s self-loading feature simplified logistics by eliminating separate batching plants and material transport. This integration yielded an estimated 15% savings in overall operational costs and reduced the carbon footprint by consolidating equipment usage.

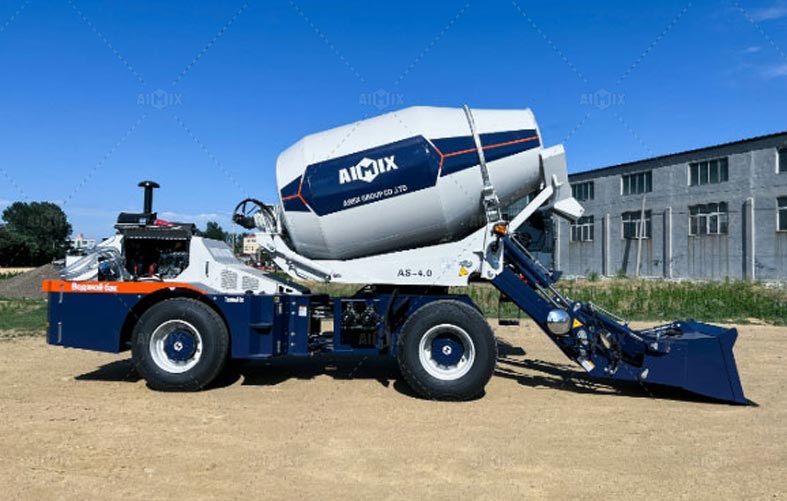

The AIMIX AS-6.5 is engineered for heavy-duty use, featuring rugged steel drums with abrasion-resistant liners to handle diverse concrete mixes — from standard to high-slump formulations. Its hydraulic control system precisely modulates mixing speeds and discharge rates, ensuring maximum flexibility for project-specific requirements.

Moreover, the vehicle’s chassis complies with international safety and emission standards, making it suitable across key global markets, including Europe, North America, and Asia. This combination of technical robustness and regulatory compliance positions the AS-6.5 as an ideal asset in the push for smarter, greener construction workflows.

Explore how AIMIX’s innovative dual helix technology can transform your project timelines and concrete quality – Discover AIMIX AS-6.5 Self-Loading Mixer Today