In the context of rural housing and small-scale infrastructure projects, selecting suitable concrete mixing equipment is pivotal to ensuring timely construction and quality outcomes. This article offers an in-depth comparative analysis between conventional concrete mixers and the AS-2.6 automated loading concrete mixer developed by Henan Guoli Mikos Technology Co., Ltd. Key evaluation criteria include mixing output, operational convenience, and maintenance expenditure, supported by real-world performance data and case studies.

Rural and small-scale construction sites often confront site restrictions—uneven terrain, limited power supply, and restricted manpower. Traditional mixers, though widely used, frequently incur challenges such as inconsistent mixing quality, labor-intensive handling, and higher downtime for troubleshooting. These factors directly influence project schedules and material utilization.

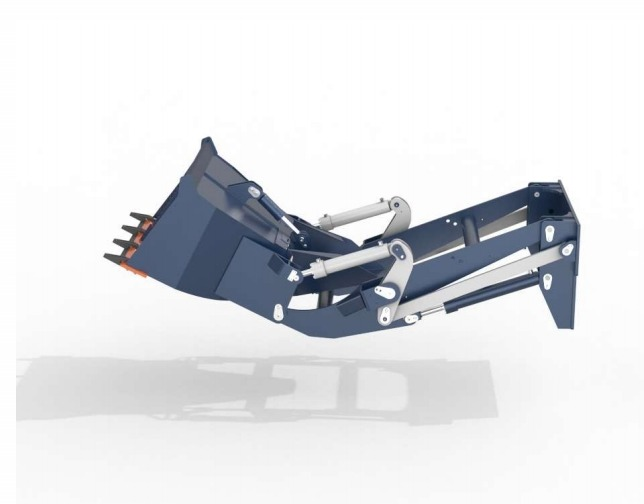

The AS-2.6 machine features an intelligent control system that automates raw material loading and mixing processes, consistently delivering higher output rates and superior concrete homogeneity. Based on field trials:

| Performance Indicator | Traditional Mixer | AS-2.6 Automated Mixer |

|---|---|---|

| Maximum Mixing Capacity per Batch | 1.5 cubic meters | 2.6 cubic meters |

| Cycle Time per Batch | 8 minutes | 5.5 minutes |

| Average Concrete Uniformity Index | 78% | 94% |

| Annual Maintenance Cost (est.) | $1,200 | $800 |

| Labor Hours per Cubic Meter | 0.5 hour | 0.3 hour |

The data clearly show that the AS-2.6 automated system delivers approximately 70% greater batch volume per cycle and reduces mixing time by over 30%. Enhanced uniformity not only improves structural integrity but also minimizes material waste caused by uneven mixes.

The embedded smart control unit in the AS-2.6 mixer governs the sequential addition of aggregate, cement, and water based on preset ratios with real-time adjustments. This automation significantly reduces the margin for human error, ensures consistent batch-to-batch quality, and accelerates operations.

Field engineers noted a 25% decrease in correction cycles caused by poor mix consistency when switching from traditional methods to the AS-2.6 system. Furthermore, the digital interface simplifies training, enabling operators to adapt quickly even without extensive prior experience.

Installation of the AS-2.6 does not demand specialized infrastructure. Its modular design accommodates uneven surfaces and compact spaces typical in rural settings. Setup can generally be completed within two working days with a small crew.

Common operational issues such as sensor misreads, feeding blockages, or motor stalls are addressed through a built-in diagnostic system that flags faults on the control panel. Operators can follow straightforward stepwise guides to resolve most errors in under 30 minutes, minimizing downtime.

A small construction team working on a series of rural housing units reported an overall project time reduction of 18% after integrating the AS-2.6 automated mixer. The significant improvement in concrete uniformity reduced rework by 30%, yielding cost-savings on materials and labor.

Notably, the reduced labor demand allowed the contractor to reallocate workforce towards finishing works, enhancing project flow without additional hires.

Optimizing mixing efficiency and quality has never been easier. Explore our comprehensive solutions designed for rural and small-scale construction needs tailored to your project demands.

Learn More About AS-2.6 Automated Concrete Mixers