Choosing the right concrete mixing equipment is pivotal for small-scale infrastructure projects and rural self-built houses, where operational efficiency, product quality, and cost control directly influence the project timeline and outcome. This article presents a thorough comparison of traditional concrete mixers versus intelligent control mixers, focusing on throughput efficiency, ease of operation, and maintenance costs. By dissecting these factors through an engineering and end-user lens, we shed light on the practical benefits of adopting advanced mixing technologies, with a particular focus on the AS-2.6 self-loading concrete mixer developed by Henan Guoli Mikos Technology Co., Ltd.

Small construction projects often grapple with fluctuating material demands and heterogeneous site conditions. Traditional concrete mixers, typically batch mixers powered by fixed motor systems, offer a throughput capacity of approximately 1.5 to 2.0 cubic meters per batch, with cycle times ranging from 5 to 7 minutes. While reliable, their batch processing leads to downtime due to manual loading and unloading, subsequently impeding continuous operation under tight schedules.

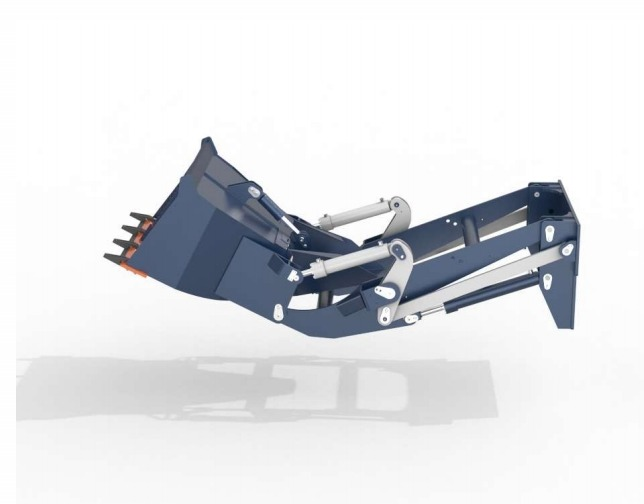

In contrast, intelligent control mixers like the AS-2.6 model deliver an aggregate mixing capacity of about 2.6 cubic meters per batch, with cycle times optimized down to 4 minutes through automated loading, mixing, and discharge sequences managed by embedded control systems. This offers throughput improvements of up to 30-40%, reducing contractor wait times and smoothing workflow continuity in challenging terrain and climatic conditions.

Manual intervention in traditional mixers necessitates skilled labor for material batching and machine asset management, increasing the risk of human error and inconsistent concrete quality. These mixers are less suited to rough site conditions where continuous manual feeding becomes impractical.

Conversely, intelligent control concrete mixers leverage programmable logic controllers (PLCs) to automate the loading, batching, water addition, and mixing cycles. The AS-2.6 model integrates a user-friendly Human-Machine Interface (HMI) touchscreen, which guides operators through preset mix profiles and allows for real-time monitoring of parameters such as moisture content, rotation speed, and mixing duration.

This automation results in consistent mix quality and significantly reduces operator fatigue and training time. Moreover, automatic error detection and alarms help maintain equipment safety and prevent downtime.

Regarding lifecycle costs, traditional mixers incur high maintenance due to manual wear on blades, motor parts, and inconsistent lubrication. These components often necessitate frequent replacements in harsh rural environments, causing unexpected project delays.

The AS-2.6 self-loading concrete mixer addresses these challenges with its robust chassis design complying with ISO 9001 and CE certifications. It features corrosion-resistant components, sealed bearings, and automatic lubrication systems that extend service intervals by approximately 25%. Predictive maintenance alerts, enabled by IoT-enabled sensors, allow timely part replacement before failures occur, reducing unplanned downtime and repair costs.

The versatility of the AS-2.6 mixer shines in environments marked by uneven terrain and climate variability typical of rural construction areas. Its self-loading function eliminates dependency on manual loaders, maintaining a steady supply of concrete on-site without labor bottlenecks. The intelligent control system adapts mixing parameters dynamically based on sensor feedback, ensuring uniform concrete consistency despite changes in raw material moisture or ambient temperature.

Field tests conducted in Henan province demonstrated a 20% reduction in concrete wastage and a 15% acceleration in overall project timelines when using the AS-2.6 model compared to conventional mixers. Additionally, operators reported easier handling and enhanced safety due to automated emergency shutdown protocols.

To maximize the value of intelligent mixers like the AS-2.6, proper installation and commissioning steps are critical. The company provides detailed manuals outlining precise grading requirements for site setup, calibration protocols for sensors, and step-by-step machine initialization sequences. Installation usually completes within 1-2 days by certified technicians, minimizing project disruption.

Common troubleshooting scenarios include sensor misalignment and software glitches, which can be resolved through remote diagnostics enabled via embedded 4G modules. This feature not only expedites issue resolution but also facilitates software updates, ensuring equipment remains compliant with evolving technical standards.

Continuous operator training modules and rapid response customer support further underpin the reliability of these advanced mixers in the field.