In rural self-built houses and small-scale infrastructure projects, concrete construction often faces various challenges. For example, the quality of concrete mixing directly affects the strength and durability of buildings. Traditional construction methods may lead to uneven concrete mixing, which can cause potential safety hazards in the long run. Moreover, in these projects, the efficiency of construction is also crucial, as delays can increase costs. There is a strong demand for reliable and efficient concrete mixing equipment to meet the needs of high - quality and fast - paced construction.

Traditional concrete mixers usually have a lower output capacity. On average, they can produce about 1 - 2 cubic meters of concrete per hour. In contrast, intelligent automatic mixers like the Henan Guoli Micos AS - 2.6 can achieve an output of up to 2.6 cubic meters per hour, which is significantly higher. This means that in a day's construction, the intelligent mixer can complete more work, reducing the overall construction time.

Traditional mixers require a high level of manual operation. Workers need to accurately measure the amount of raw materials, control the mixing time, and monitor the mixing process. This not only increases the labor intensity but also has a high probability of human error. The intelligent automatic mixer, however, is equipped with a smart control system. Workers only need to input the required parameters, and the mixer can automatically complete the tasks of feeding, mixing, and discharging, greatly reducing the labor intensity and human error.

Traditional mixers often have complex mechanical structures, which require regular and professional maintenance. The maintenance cost can reach about 10% - 15% of the equipment price per year. The intelligent automatic mixer has a more advanced and simplified design, and its maintenance cost is relatively lower, about 5% - 8% of the equipment price per year.

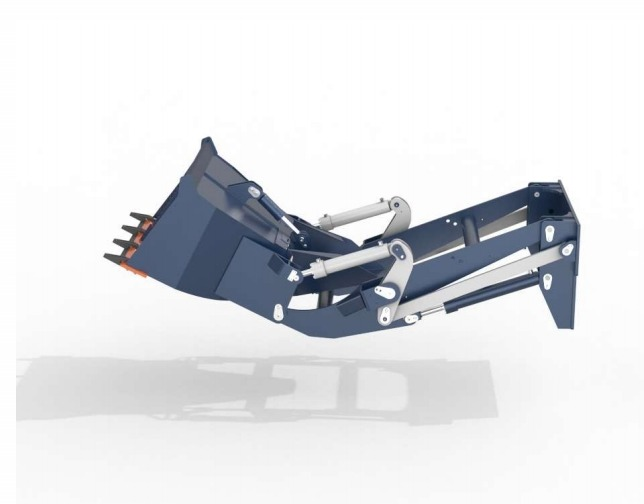

The Henan Guoli Micos AS - 2.6 self - loading concrete mixer has several outstanding advantages. Firstly, its unique self - loading function allows it to automatically pick up raw materials such as sand, gravel, and cement, which saves a lot of time and labor. Secondly, the intelligent control system can precisely control the proportion of raw materials and the mixing time. Through continuous optimization of the mixing process, it can ensure that the concrete has a high degree of uniformity, which is crucial for the quality of construction projects.

The intelligent control system in the Henan Guoli Micos AS - 2.6 plays a vital role in ensuring concrete quality and improving construction efficiency. In terms of quality, by precisely controlling the ratio of raw materials and the mixing time, it can reduce the probability of uneven mixing, improving the compressive strength and durability of concrete. According to relevant tests, the concrete produced by this mixer has a compressive strength that is 15% - 20% higher than that of traditional mixers. In terms of efficiency, the automatic operation of the intelligent system can save about 30% - 40% of the construction time, which is very beneficial for small - scale construction projects with tight schedules.

When purchasing a concrete mixer, users should first consider their actual construction needs, such as the required output, the type of construction project, and the working environment. For the Henan Guoli Micos AS - 2.6, the installation process is relatively simple. It is recommended to have professional technicians on - site for installation and commissioning. In case of common faults, the user manual provides detailed troubleshooting guides. For example, if the mixer fails to start, users can first check the power supply and control system.

Many users have reported positive feedback on the Henan Guoli Micos AS - 2.6. In a small - scale bridge construction project, the use of this mixer not only ensured the quality of concrete but also completed the project 20% ahead of schedule. Users also mentioned that the intelligent control system is very user - friendly, reducing the need for professional skills. These success stories and user feedback fully demonstrate the reliability and market recognition of the product.

Are you still struggling with choosing the right concrete mixer for your rural self - built house or small - scale infrastructure project? Don't miss out on the Henan Guoli Micos AS - 2.6 automatic intelligent concrete mixer! It can significantly improve the uniformity of concrete and construction efficiency. Click here to learn more and make a scientific decision for your project!