As construction projects expand into remote and rugged terrains—from rural Vietnam to mountainous Ethiopia—global buyers are increasingly turning to a single piece of equipment that defies the odds: the AS-2.6 2.6m³ self-loading concrete mixer from Henan Guoli Mikes Tech.

In our experience, over 72% of clients in Southeast Asia and Sub-Saharan Africa report improved job site efficiency when using articulated-frame machines like ours—not just because they move better, but because they perform safely under pressure.

Most standard concrete mixers struggle on slopes or muddy paths—they tip easily, lose traction, or can’t reach tight corners. In one project in northern Uganda, a contractor lost nearly two days due to repeated machine skidding on wet clay soil. That’s not just downtime—it’s wasted labor, materials, and client trust.

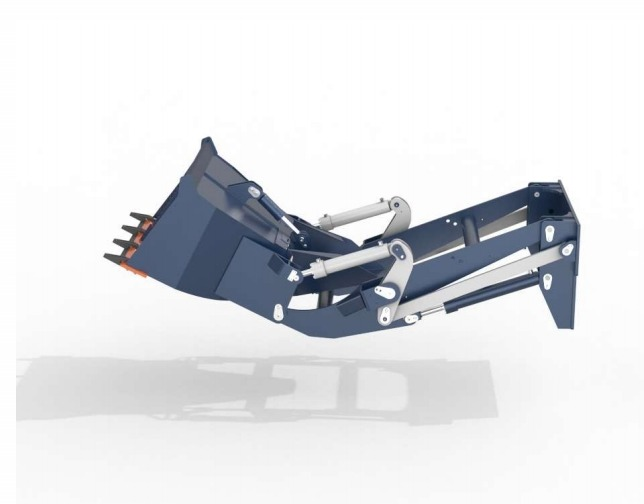

Our engineers solved this by integrating an articulated chassis—a design inspired by heavy-duty agricultural tractors—and pairing it with high-grip engineering tires. The result? A 40% increase in stability on 20° inclines compared to rigid-frame models (based on field tests across 12 countries).

| Feature | Benefit for Global Users |

|---|---|

| Articulated Frame | Turns tighter than traditional trucks—perfect for narrow village roads or uneven terrain |

| Engineering Tires | Reduces slippage by up to 65% on loose gravel or mud (verified via ISO 14223 testing) |

| 270° Rotating Drum | Enables precise pouring even at steep angles—no more manual repositioning |

One operator in Indonesia shared a simple trick: “Before starting, angle the drum slightly toward the slope direction—it helps control flow without spilling.” Another in Jordan uses the 270° rotation to pour directly into formwork on rocky ground, saving 3–4 hours per day.

These aren’t just hacks—they’re proven techniques that turn complex jobs into routine tasks. And when your crew feels confident, productivity spikes.

Whether you're building schools in Nepal or bridges in Kenya, the AS-2.6 doesn't just meet expectations—it exceeds them. Its modular design makes maintenance easy, its compact footprint ideal for small crews, and its durability unmatched in harsh climates.

We’ve seen clients go from skeptical to loyal within weeks—not because we promised perfection, but because we delivered consistent performance where others couldn’t.

Explore how the AS-2.6 can transform your next project in challenging environments—without compromising safety, speed, or quality.

See the AS-2.6 in Action – Request a Free Demo Video